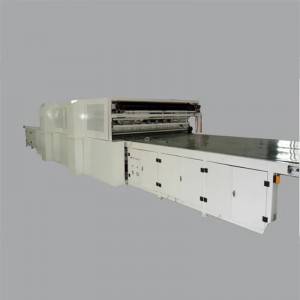

Silicone Rubber Cushion Bakeng sa Laminator ea ho etsa likarete

Tlhaloso ea Sehlahisoa

Mosamo oa rabara oa silicone bakeng sa laminator ea ho etsa likarete e entsoe ebile e etsoa ke k'hamphani ea rona e ikemiselitseng ho tšehetsa indasteri ea ho etsa likarete ho latela tlhoko ea 'maraka, e loketseng mefuta eohle ea likarete tsa banka, likarete tsa mekoloto le tlhahiso ea likarete tse bohlale.

Mosamo oa rabara oa silicone o hlahisoang ke k'hamphani ea rona o sebelisa mefuta e 'meli ea sebopeho sa sebopeho, e leng KXM4213, rabara ea silicone e mahlakoreng a mabeli e nang le mohlala, lesela la fiberglass e bohareng.KXM4233, mahlakore a mabeli a ne a utloahala, rabara ea silicone e bohareng.

KXM4213 (rabara ea silicone ea mahlakore ka bobeli e nang le mohlala, lesela la fiberglass e bohareng)

Lintho tse tala tse tsoang Jeremane, tse hanyetsanang le mocheso o phahameng, elasticity e ntle

Mocheso o tsamaisang ka potlako, Mocheso o ajoa ka mokhoa o ts'oanang

Molemo o motle oa ho hanyetsa khatello e phahameng.

Ha e khone ho qhibiliha, ha e tsofale, e hanela ho bola.

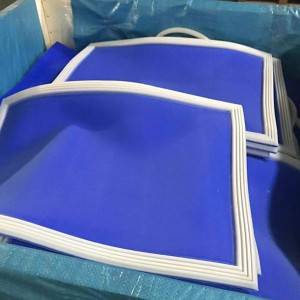

KXM4233 (mahlakore ka bobeli a ne a utloahala, rabara e bohareng ea silicone)

Lintho tse tala li ka mamella mocheso, li hanana le khatello e phahameng.

Mocheso o tsamaisang ka potlako, Mocheso o ajoa ka mokhoa o ts'oanang

Monyetla o motle oa metsi, o ka tlosa bubble le watermark ea karete ea bokaholimo.

Buffering e ntle, e lelefatsa bophelo bohle ba boto ea ho futhumatsa le boto ea laminating.

Lihlahisoa tsa lihlahisoa

| Ntho | KXM4213 | KXM4233 |

| Lintho tse ka holimo | Rabara ea silicone e nang le mohlala | Maikutlo a hanyetsanang le mocheso |

| Lintho tse bohareng | Lesela la fiberglass | Rabara e ntšo ea silicone |

| Lebōpo la Hardness A | 55±5 | 50±5 |

| Matla a ho tiea(N/mm) | 80 | 60 |

| Ho khomarela(N/mm) | 4.5 | 4.5 |

| Ho hanyetsa mocheso ℃ | 230 | 200 |

| Mmala | Bosoeu | tšoeu |

Litšobotsi tsa eona ke tse latelang:

(Lesela le nang le mahlakore a mabeli la silicone bohareng ba fiber)

•Sehlahisoa se amohela lisebelisoa tse tala tse tsoang linaheng tse ling tsa Jeremane, ho hanyetsa mocheso o phahameng le ho feto-fetoha ha maemo hantle.

• Ho tsamaisa mocheso o potlakileng le kabo ea mocheso o ts'oanang ho ka eketsa haholo tlhahiso ea sehlahisoa nakong ea ts'ebetso ea lamination.

• E na le ho hanyetsa khatello e ntle, ha ho na deformation, e ka tšeptjoang le e tšoarellang.

•E thusa ho felisa likoti le lijo-thollo tse ntle holim'a metsi le ho ntlafatsa boleng ba sehlahisoa.

• Ho hanyetsa ho qhibilihisa, ho hanyetsa botsofali, ho hanyetsa ho bola, ho se chefo le ho hloka monko, ho latela litlhoko tsa tšireletso ea tikoloho.

• Thepa e tala ea sehlahisoa e ka mamella mocheso o phahameng le khatello, e finyella litlhoko tsa theknoloji ea ho etsa likarete le ho lamination, 'me e sebelisoa haholo e le lisebelisoa tse khethehileng tsa ho etsa likarete.

• Ho tsamaisa mocheso o potlakileng le o ts'oanang, ho ntlafatsa katleho ea tlhahiso le ho boloka matla.

• E na le ts'ebetso e ntle ea ho monya metsi, e ka felisa ka katleho li-bubble le li-watermark holim'a karete, 'me e ntlafatsa haholo tekanyo ea ho tšoaneleha ha sehlahisoa.

• E na le ts'ebetso e ntle ea cushioning, e qoba matšoao a marang-rang a bakoang ke ho kopana ka thata pakeng tsa poleiti ea ho futhumatsa le laminate, 'me e lelefatsa bophelo ba tšebeletso ea poleiti ea ho futhumatsa le laminate.

• Ho bonolo ho e sebelisa, 'me e boloka lihora tsa motho.